|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

Powered by: Sun Microsystems |

|

Battery

Products

Example: Forklift Battery Watering System

Automatic Watering System

| Filler is Easily

Accessible | 5gal.

Reservoir | Water Level Indicator

The five most common

reasons for Premature Battery Failure: Low water levels

· From our experience, this is the number one cause of battery failure. ·

Charging batteries that are as

little as 1” low on water can cause damage to the entire battery that can

never be repaired. It dries and burns the uppermost portion

of the “plates”, causing high resistance that is permanent, and

effectively isolates the portion that remained submerged. ·

Even when the proper water levels are restored, the damaged

portion continues to cause high resistance and the battery runs much hotter

from that point forward, causing accelerated water loss and further plate damage due to overheating. Over Charging and

Opportunity Charging

·

Industrial batteries are typically

designed to last at least 1,500 charge cycles, over

a five to fifteen year period. Each time you charge a battery, regardless of

how long, it constitutes one cycle. ·

Consistently charging a battery

twice per day, during lunch breaks for example, is known as Opportunity

Charging, and reduces the useful life of a battery by 50%. ·

The additional heat generated by opportunity

charging a battery usually reduces the run time equal or greater in

proportion to the amount of charge it actually received, making the practice

completely ineffective and costly. ·

Routinely charging the battery

before it is 80% discharged is another common form of over

charging. For example, if you only use the battery a few hours a day, it’s

best to use it until it is truly in need of charging before actually plugging

it in. Remember, each charge constitutes one cycle, so try not to charge

unnecessarily. Over watering

·

Commonly occurs as a reaction to low

water levels, but is a major problem unto

itself. ·

Flushes the electrolyte from the cells and gradually dilutes the acid to the point that the battery can no

longer function properly. In many cases this can be remedied sending the

battery out to have the acid adjusted, but the battery’s life will still be

shortened somewhat. ·

Causes tray corrosion (listed

below). Failing to Equalize Charge

·

Batteries should receive an Equalize

Charge once every 10 cycles. ·

Almost all chargers are equipped

with an Equalize feature. On older chargers, this setting is usually referred

to as Weekend or Weekly charge. ·

Selecting this setting adds 3

additional hours to a normal charge, ensuring all of the cells in the battery reach full charge, and

the allowing extra time for the electrolyte to mix during the Gassing

Stage. ·

Failure to equalize causes reduced

battery run time and eventual failure, due to Sulfation, Stratification, and

an imbalanced capacity between the cells. Battery Corrosion

·

Batteries should be rinsed or washed

at least once per year to prevent corrosion. ·

Even when the proper water levels are consistently

maintained, sulfuric acid vapors escape during charge.

These vapors leave an oily sulfuric acid residue on the top of the

battery around the vent caps. Over time, the water in the residue evaporates

leaving full strength, concentrated acid that is much more concentrated than

the diluted acid inside the battery. ·

The concentrated acid is very

conductive. As it gradually accumulates and spreads out, it eventually makes contact

between the intercell connectors across the top of the battery. This results

in shorting between the cells, causing the battery to self-discharge, and additional heat during charge

and use. ·

Even though battery trays have a

baked on powder coat finish, they will easily corrode if the residue is not

rinsed off. The corrosion will become progressively worse until it is either

removed, or it destroys the battery. |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

CABLE CORROSION

– REPAIRABLE:

This is a commonly overlooked problem which causes reduced

run time and all of the classic symptoms of a bad battery or cell. Many times this is the only problem,

and replacing the corroded cable increases run time dramatically. ·

CAUSE:

If the battery is not rinsed periodically, acid penetrates the seal between the cable

head and the insulation and begins to oxidize and corrode the copper

conductors. The cable gradually swells over time as the copper breaks down,

deteriorating the connection gradually until the battery no longer accepts a

charge. Examples of Battery Cable Corrosion: Swollen near

terminal, copper is replaced by blue corrosion.

Positive Plate Growth

– NOT REPAIRABLE:

The true sign that a battery has reached the end of its

useful life, and is in need of replacement. Typically begins to occur after 5

years. As batteries age, the positive plates begin to soften and expand in size.

This causes internal pressure inside the battery cells. Most manufacturers now use floating

bushings on the positive cell posts to allow for this gradual

expansion and reduce stress on the cells internal components. Eventually, as

the battery reaches the end of it’s normal useful

life, the internal pressure is great enough to push the positive posts well

beyond normal tolerances and can begin to distort the cell covers and vent wells. Positive plate growth is normal and should be

considered as a wear indicator. If your battery is no longer holding a charge

and shows signs of plate growth, it should be replaced, not

repaired. ·

Batteries can fail and be beyond

economical repair without showing noticeable signs of plate growth. However, plate growth is a sure, visible sign that

the battery is beyond economical repair. ·

Positive plate growth typically occurs after 5 years

or 1,500 cycles. If it occurs in less than 5 years, it is most likely due to

opportunity charging or over charging, which should be addressed when

replacing the battery. ·

This condition usually affects the Positive posts only, and

will give an uneven, slanted appearance when viewed from the side, looking

across the top of the battery. Examples of Positive Plate Growth:

·

SHORT

RUN TIME: Progressively shorter run times could be

caused by a malfunctioning battery OR charger. It is best to have both

checked if you begin to experience shortened run time or suspect a problem. ·

EQUALIZE

CHARGE: Industrial batteries must receive an

equalize charge at least once per month, or permanent damage will result.

Never equalize more than once every 5th charge cycle, or damage will result. Reason:

Selecting equalize mode on your charger adds 3 additional hours of charge

time to that charge cycle, ensuring all of the cells reach 100% charge. Equalizing too

often or too little will shorten battery life. ·

WHEN TO

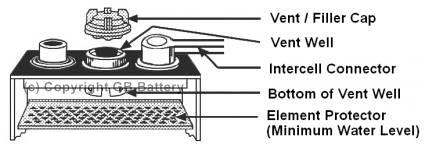

ADD WATER, AND HOW MUCH TO ADD: Water can be

added before or after charging. Add just enough water to cover the perforated

element protector (visible at the bottom of the vent well). ·

·

WHAT

KIND OF WATER TO USE: In general, normal city water will

suffice, but if you have any doubts about purity of the local water supply,

A) contact the GB battery supplier in your area B) get a chemical analysis of

the water C) use distilled water. ·

·

SPECIFIC GRAVITY (SPGR): See SPGR chart

below. ·

OVER DISCHARGING: Never over

discharge batteries. More is not necessarily

better when it comes to recharging batteries. Most battery manufacturers

warrant their batteries for up to 1,500 cycles of charge and discharge provided, among other things, that

the battery is never discharged beyond 80%. This normally

coincides with an eight-hour shift. Trucks fitted with extra equipment such

as clamps, high speed lifts, etc. will need a higher capacity battery to ensure the battery is

not discharged beyond 80%. Lift truck

interrupts are available to detect the correct discharge level and are recommended by battery

manufacturers as a means of ensuring batteries are not over discharged. The best way to ensure batteries

are not being overcharged is to periodically (once a

month) check the temperature of the center cell on a battery at the end of regular

charge. If the temperature of the electrolyte is more than

36° F above the ambient temperature, call your battery technician—

there is a problem. ·

AVOIDING SPARKS: Batteries produce

and store hydrogen gas, which is highly explosive. Never weld near a battery.

Never place metal objects on batteries. Such

objects can cause a short circuit between adjacent cells and result in possible injury to those

close to the battery. Similarly, people charged with caring for or operating

batteries should not wear any metal jewelry. ·

UNDER-SIZED CHARGERS: A charger that is

more the 100AH less than the your battery’s rated capacity.

Will result in an undercharged battery with significant reduction in

operating life. Your local GB vendor has all the information to ensure the

battery and chargers are precisely matched. ·

OVER-SIZED CHARGERS: A charger that is

over 100AH more than your battery’s rated capacity.

Can overcharge and overheat your battery, reducing the operating

life of your battery. ·

WHEN TO

REPLACE A BATTERY: Repair or replace batteries when capacity that has fallen below 80% of its

rated capacity. Continuing to operate a bad

battery can damage a truck's electric motor and electronics. Failing

batteries also require recharging more frequently, wasting hundreds or thousands

of dollars in energy per year, depending on the size of your fleet. ·

RECORD

KEEPING: We recommend that each forklift, battery

and charger in your fleet be given a unique number for easy identification

and tracking purposes. Keep regular records on the maintenance of batteries.

For instance, keep a log of ever time a battery is watered and equalize

charged, or at minimum, each time an operator complains of short run time and

whenever cells or cables are replaced. These records

will be invaluable when it comes to predicting when battery replacement will

be necessary. ·

FORMULAS:

§ Charger Model# Breakdown: Example, Model GB100-3-18-750 = GB brand, 100% rated, 3 phase, 18 cell (36 volt), 750AH (Ampere Hour). § Battery

Model# Breakdown: Example, Model 18-125-13 = 18 cells (x2 = 36 volt), 125AH per plate, 13 negative plates. § Calculating

AH Capacity: Negative plates per cell – 1, / 2 x AH per plate = AH (Ampere Hour). § Example,

18-125-13: 13 – 1 = 12, / 2 = 6 x 125 = 750AH § Calculating

KWH Capacity: AH x

Volts (2v per cell) = WH (Watt Hour) / 1000 x .97

(efficiency factor) = KWH (Kilo Watt Hour) § Example,

battery model 18-125-13, 36V / 750AH: 750 x 36 = 27,000 / 1000 = 27 x .97 =

26.19KWH. ·

STATE OF CHARGE: Typical

no-load voltages vs. state of charge:

§ Sample

voltages are for a 12-volt / 6 cell battery system (figured at 10.5 volts =

fully discharged, and 77 degrees F). For a 24-volt

battery multiply by 2, for a 36-volt battery multiply by 3, 48-volt battery

multiply by 4. VPC is the volts per individual cell - if you measure more than a .2 volt

difference between each cell, you need to equalize, or the battery

is beginning to go bad, or it could be sulfated. These voltages are for

batteries that have been at rest for 3 hours or more. Batteries that are

being charged will be higher - the voltages while charging will not tell you

anything, you have to let the battery sit for approx. 3hrs. For longest life,

batteries should stay in the green zone. Occasional dips into the

yellow are not harmful, but continual discharges (or “cycles”) to those levels will shorten

battery life considerably. It is important to realize that voltage

measurements are only approximate. Note the large voltage drop in the

last 10%.

Other Battery Questions and Answers

How are batteries rated and what

do the ratings mean in battery selection? How does the Cold Cranking Amperage rating help me select

a battery? What does the Reserve Capacity rating mean and how does

it apply to deep cycle batteries? What is

the difference between deep cycle batteries and starting batteries? Does overcharging damage batteries? Does over discharging damage batteries? How can I evaluate the health and state of charge (SOC)

of a battery?

1) BATTERY

RATINGS

|

|

||||||||||||||||||||||||||||||||||||||||||||||

Fork truck battery for sale, forklift batteries for

sale

Forklift Batteries New York NY

Forklift batteries New Jersey NJ

Reconditioned forklift batteries, Lift Truck batteries

Industrial forklift batteries, Industrial forklift

battery chargers

Forklift battery Orlando Florida FL

Forklift battery Los Angeles California CA

Forklift Battery, Lift Truck Battery, Fork Lift

Battery, Fork Truck Battery

Forklift battery, Lift Truck Battery Chicago Illinois

IL

Lift Truck Battery Pennsylvania PA

Phoenix Forklift Battery Arizona

Fork Truck Batteries, Forklift Batteries

Forklift Batteries Inc, Batteries Inc Maryland MD

Lift Truck Batteries, Fork Lift Batteries

Forklift battery Atlanta Georgia GA

West Michigan Battery, Forklift Batteries

Extra Power Battery, Xtra Power Battery

Texas Industrial Battery, Lift Truck Battery TX

Forklift Battery, Dallas TX, Houston TX, Austin TX

Forklift Battery NJ New Jersey

http://forkliftpower.com/6-85-11.com/index.html

http://forkliftpower.com/6-85-13.com/index.html

http://forkliftpower.com/6-100-13.com/index.html

http://forkliftpower.com/6-125-13.com/index.html

http://forkliftpower.com/24v-battery.com/

http://forkliftpower.com/12-85-5.com/index.html

http://forkliftpower.com/12-85-7.com/index.html

http://forkliftpower.com/12-85-13.com/index.html

http://forkliftpower.com/12-85-7.com/index.html

http://forkliftpower.com/12-85-19.com/index.html

http://forkliftpower.com/12-85-21.com/index.html

http://forkliftpower.com/12-85-23.com/index.html

http://forkliftpower.com/12-100-13.com/index.html

http://forkliftpower.com/12-125-11.com/index.html

http://forkliftpower.com/12-125-13.com/index.html

http://forkliftpower.com/12-125-15.com/index.html

http://forkliftpower.com/12-125-17.com/index.html

http://forkliftpower.com/36v-battery.com/

http://forkliftpower.com/18-85-13.com/index.html

http://forkliftpower.com/18-85-15.com/index.html

http://forkliftpower.com/18-85-17.com/index.html

http://forkliftpower.com/18-85-19.com/index.html

http://forkliftpower.com/18-85-21.com/index.html

http://forkliftpower.com/18-85-23.com/index.html

http://forkliftpower.com/18-85-25.com/index.html

http://forkliftpower.com/18-85-27.com/index.html

http://forkliftpower.com/18-85-29.com/index.html

http://forkliftpower.com/18-85-31.com/index.html

http://forkliftpower.com/18-85-33.com/index.html

http://forkliftpower.com/18-125-11.com/index.html

http://forkliftpower.com/18-125-13.com/index.html

http://forkliftpower.com/18-125-15.com/index.html

http://forkliftpower.com/18-125-17.com/index.html

http://forkliftpower.com/48vbattery.com/index.html

http://forkliftpower.com/24-85-13.com/index.html

http://forkliftpower.com/24-85-15.com/index.html

http://forkliftpower.com/24-85-17.com/index.html

http://forkliftpower.com/24-85-19.com/index.html

http://forkliftpower.com/24-85-21.com/index.html

http://forkliftpower.com/24-85-25.com/index.html

http://forkliftpower.com/24-85-27.com/index.html

http://forkliftpower.com/24-125-13.com/index.html